SoundPLAN GmbH... Despite worldwide activities, SoundPLAN GmbH has remained on the carpet. As always, they provide personal, friendly advice in a familiar environment. Thanks for the last 20 years.

SoundPLANnoise... An easy to use and very intuitive program. Powerful tool for DGM creation, which even our surveyor is enthusiastic about. Very good documentation possibilities in graphics and tables.

Water and Transport Kontor GmbH

Michael Hinz

www.wvk.sh

SoundPLAN GmbH... We have been working with the software of today's SoundPLAN GmbH for many years. During this time, we have come to appreciate this company not only for its expertise, but also for its strong customer orientation.

SoundPLANnoise... SoundPLAN has undergone an impressive development from a rather simple calculation tool for traffic noise to a comprehensive and versatile sound calculation program. A dedicated hotline helps with application problems. Occurring program errors are corrected consistently and on short notice.

Bonk-Maire-Hoppmann PartGmbB

www.bmh-ingenieurbuero.de

SoundPLAN GmbH... is close to the users of its software and fast in support.

SoundPLANnoise... is currently the most user-friendly and powerful software in the field of noise immission control.

SoundPLAN GmbH... We appreciate the friendly, competent and innovative support we have been receiving for many years now, just as we did on the first day of our business relationship!

SoundPLANnoise... From simple to very complex questions; the SoundPLAN program provides everything for expert opinions, quantitatively and qualitatively. It is constantly being further developed with engineering and programming expertise.

SoundPLAN GmbH... Very committed team with always helpful hotline.

SoundPLANnoise... Fast and comfortable to use with good graphical representation for both digitization and documentation.

TAC

Klaus Boehmer

www.tac-akustik.de

SoundPLAN GmbH... nice employees - always ready to help.

SoundPLANnoise... Operation + documentation are very good. Own improvements and suggestions are always taken up and partly already considered.

TAC

Ulrich Wilms

www.tac-akustik.de

If you really need the hotline, you will get a solution!

SoundPLANnoise... comfortable, self-explanatory, comprehensive.

www.igbv.de

SoundPLAN GmbH... competent and customer-oriented. The hotline is always easy to reach and you will normally receive immediate help.

SoundPLANnoise... user-friendly & innovative. The program is easy and intuitive to use and supports the project process very well.

Dipl.-Ing. K. Langenbach GmbH

Sara Köhler

www.langebach.de

SoundPLAN GmbH... is a friendly and technically competent team with a dedicated support team!

SoundPLANnoise... user-friendly program in GIS-optics!

www.ebb-gmbh.de

SoundPLAN GmbH... is a very customer-oriented software manufacturer. I appreciate that very much.

SoundPLANnoise... offers numerous options for the calculation, evaluation and presentation of the desired data as well as a neat user interface.

Johanna Weißkopf

SoundPLAN GmbH... The good work of the founders, Mr. Braunstein and Mr. Berndt, has been continued by the new team since 2014. Also the fast and reliable hotline as well as the versatile user days are great!

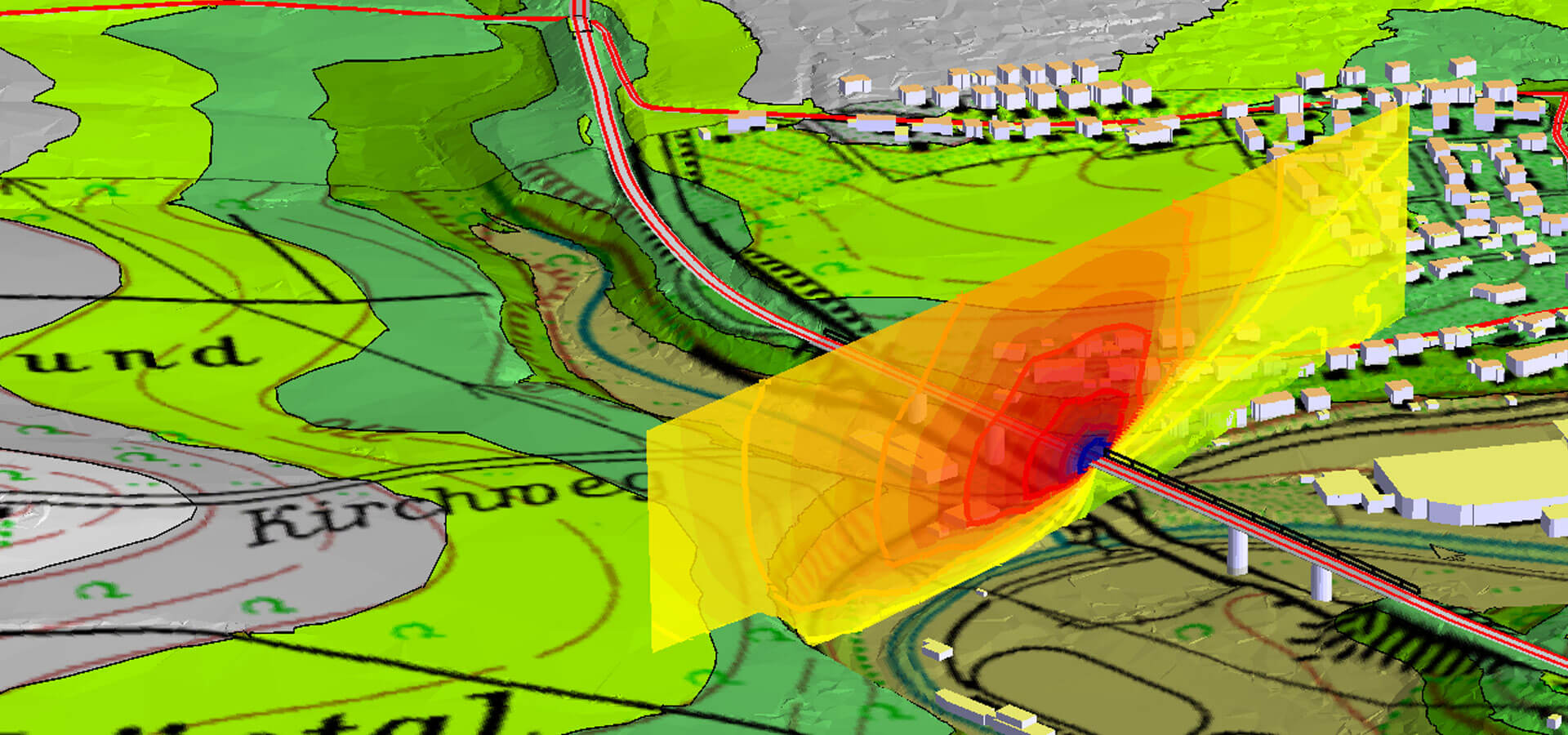

SoundPLANnoise... We have been using SoundPLAN since 1991, when it was still called SCHALLPLAN. We are active in the field of noise protection on traffic routes.

VIC Planning and Consulting GmbH

Dr.-Ing. Mario Schiffel

www.vic-gmbh.de

When we need it, we always get quick and efficient support.

The program contains all the calculation models that we need.

We use the program to calculate noise propagation from industry, roads and railways.

Use of the SoundPLAN requires good knowledge of the calculation models used, and training in the use of the program is required.

There are many possible settings of calculation parameters that affect the calculation results. A better overview of selected settings could be desired.

Rambøll, Danmark

Ole Funk Knudsen

www.ramboll.com

SoundPLAN software has assisted in our projects which covers environmental, industrial and transportation noise. The software is user-friendly and versatile which allows us to provide our wide range of clients with the best noise simulations and graphics.

Acoustech consulting

Oliver Knopperson

www.acoustech.co.za

SoundPLAnoise is a good tool for government organizations that oversee environmental aspects like noise pollution. Specifically, in local governments it can be used to generate high-quality information to access whether the permitted noise level a being met, so the authorities can make informed decisions to resolve the problem. It can also help at the planning level of a project for establish the noise levels to which the population will be exposed because of this. About the platform it has a pleasant interface with the user, it is possible to use different input data formats and resources from bing maps. It can be evaluated the noise from rail, road, and industry. Noise maps can be generated for the indices Ld, Le, Ln and Lden, for facades and acoustic conflict.

Minicipalidad de Guatemala

Ana Sánchez

www. muniguate.com

We choose SoundPLAN because it is widely renowned and accepted. It helps us convince clients with the calculation behind the modelling and simulation as it applies international standards. Its performance helps us boost our productivity and it is supported with complete user’s manual and excellentafter-sales service support.

PT Indoakustik Rekayasa Utama

Ivan Stefanus

www.indoakustik.com

With basic purchase of SoundPLANessential, I could get result of noise distribution in onshore facility with noise input of each source. However, I got difficulty to switch 3D View to top view, it always error. Hope the software could improve regarding this matter. Having one day training is helpful to ease the use of this software. If you want to have some simulation cases, it will be better to purchase SoundPLANnoise with modular.

PT. Pratiwi Putri Sulung

Ardina Lukita Diyani Putri

www.pratiwi.com

SoundPLAN’s software is very useful software to make planning and design for sound barrier highway, railway and other purpose.

PT MEGA KARYA SAMPURNA

Hendrik Sudharsono

www.mksampurna.com

SoundPLANnoise ...

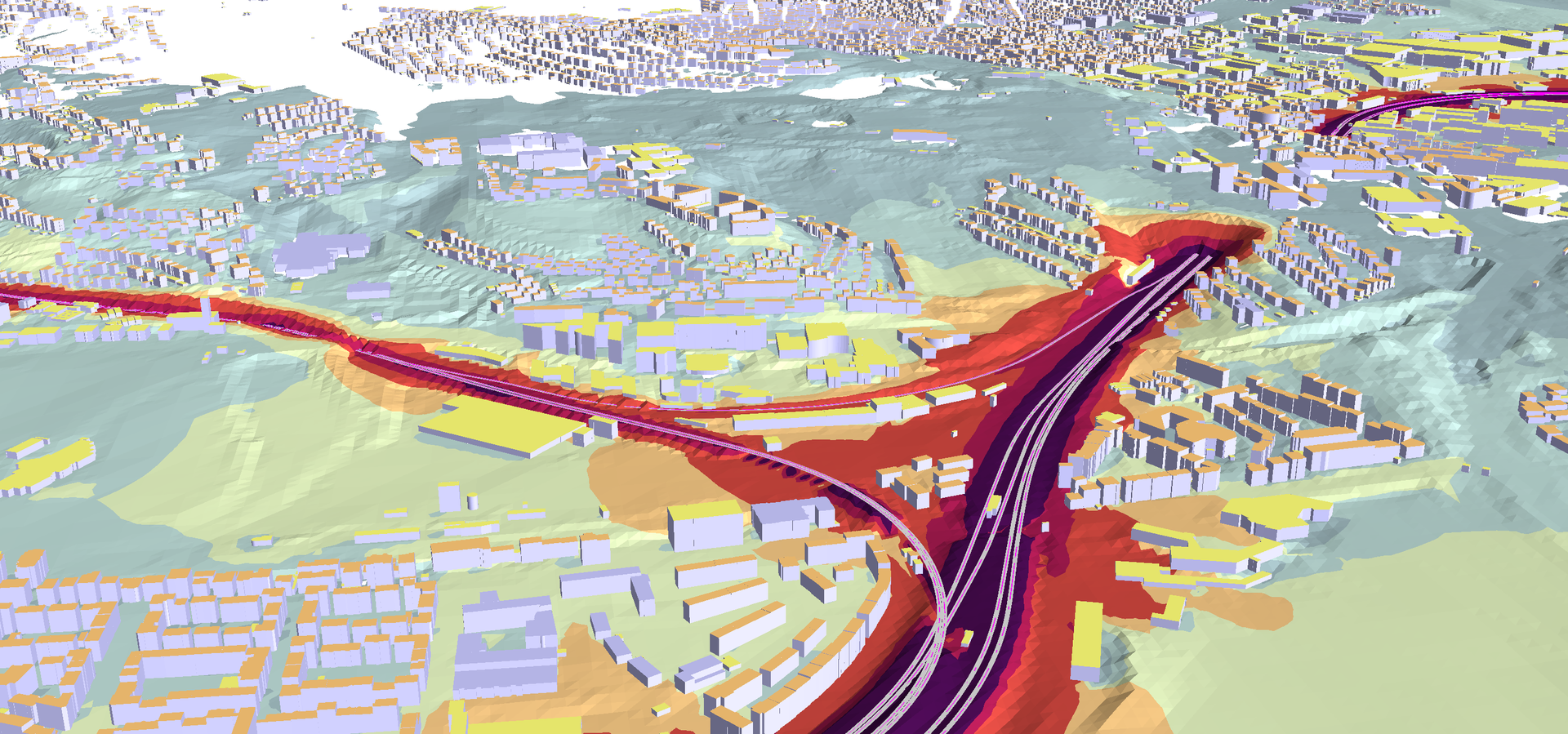

I have been using SoundPLAN software since 2017, initially in the essential version, but currently in the SoundPLANnoise (64-bit) version, mainly for the purposes of modeling the predicted acoustic impact of transport infrastructure investments. The possibility of importing data from various sources and the permissible scope of their editing greatly facilitates work on a given project, significantly reduces the time of data preparation for final calculations.

While working with the program, I have not encountered a situation where an error occurred which would result in data loss, which is very important for me. In addition, the ability to export the results obtained, including isophones, allows you to freely adjust the method of data presentation to the specific requirements of the customer. Working with the program does not pose difficulties, certainly a big advantage is the possibility of temporary rental of individual modules under a given demand. In the course of time, on the basis of my professional experience with the SoundPLAN software, I can surely state that working with such advanced software brings only benefits. I recommend it further.

Praca Na Zielono Adam Jeż

Adam Jeż

www.pracanazielono.pl